As our very first facility in Punjab and our HQ, this location holds a significant place in our company's history. It houses a machine shop which primarily supports our Derabassi foundry, and it also functions as our core design and development center.

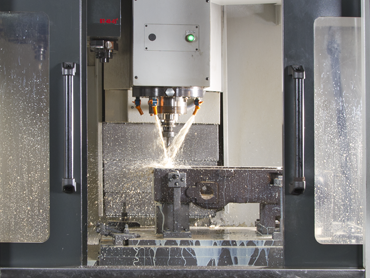

The machine shop features a broad range of equipment—from traditional machines to advanced high-precision HMCs VMCs VTL’s. Like all our machine shops, it includes a fully equipped scanning room and CMMs (2), ensuring top-tier quality control.

This unit marked our entry into the casting industry as our first foundry. It was a backward integration to supplement our existing machine shops, and began with an annual capacity of 3,000 MT. Today, after years of expansion and innovation, the unit has grown to an capacity of 18,000 MT per year, reflecting our commitment to continuous improvement and industry leadership. This facility has been instrumental in driving our company's evolution and scaling our production capabilities

PAIL UNA was established in 2006 to meet the rising demand for castings in North India. Strategically located to be closer to our key customers, this unit became our first fully integrated plant, combining casting and machining operations at the same location. Originally launched with an annual capacity of 8,000 MT, it has since expanded to 24,000 MT annually. Our commitment to growth extends beyond foundry operations-machining capacity at this facility has also tripled, thanks to the continuous addition of advanced, high-quality machinesmanufactured by Mazak, Ace, BFW and more.

Established in 2018 with an initial capacity of 6,000 MT per year, PEC is a key part of our growth strategy. It is our second fully integrated facility, housing both foundry and machining operations in one location. Over the past six years, the plant has rapidly expanded its capacity to 18,000 MT annually, while the machine shop has tripled in size, now featuring cutting-edge, high-precision machinery. This growth showcases our dedication to innovation, operational excellence, and meeting the evolving demands of the industry.

Meeta Castings, located adjacent to PEC, is the latest addition to our manufacturing capabilities and India's first dedicated Lost Foam Casting (LFC) facility. Launched with an initial capacity of 12,000 MT/year, it is designed to scale up to 21,000 MT/year as demand grows. This facility allows us to cast large, heavy components up to 500 kgand leverages the PEC machine shop for machining, thanks to their strategic proximity. This expansion reflects our commitment to innovation, diversification, and pushing our boundaries of manufacturing excellence.

| Plants | Casting Type | Moulding Lines | LFC | Furnaces |

Plant Capacity (MT/Month) |

Additional Capacity (MT/Month) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

ARPA 900 DISA |

ARPA 450 DISA |

ARPA 300 DISA |

HPML DISA MATCH 130 |

1.5 TONS |

1.0 TONS |

2.0 TONS |

|||||

| PAIL-1 | GREY IRON | 1 | 1 | 1 | 1 | 2 | 1500 | ||||

| PAIL-2 | GREY IRON & DUCTILE (SG) IRON | 2 | 1 | 2 | 5 | 2000 | |||||

| PEC | GREY IRON & DUCTILE (SG) IRON | 1 | 1 | 2 | 2 | 1500 | 500 MT by 2026 | ||||

| MC | GREY IRON & DUCTILE (SG) IRON | 1 | 1 | 1000 | 750 MT by 2025 | ||||||

| PRITIKA GROUP OF INDUSTRIES |

4 | 2 | 1 | 1 | 1 | 5 | 9 | 1 | 6000 | 1250 | |

| 7250 | |||||||||||

Pritika Group of Industries produces 100% machined castings. We have a dedicated machining facility for all our foundries with the latest and best machines and quality equipment.

| Machine | Machine Make | Quantity | |

|---|---|---|---|

| HOIRIZONTAL MACHINING CENTRE | HMC | MAZAK, DOOSAN BFW, ACE, HMT | 48 |

| VERTICAL TURNING CENTRE | VTL | TONGTOI, BFW, LOKESH | 14 |

| VERTICAL MACHINING CENTRE | VMC | DOOSAN, LOKESH, BFW, ACE | 24 |

| VERTICAL MACHINING CENTRE DOUBLE PALLET |

VMC | DOOSAN, LML, BFW, ACE | 13 |

| VERTICAL MACHINING CENTRE 4TH AXIS |

VMC | FANAUC, BFW, LOKESH | 8 |

| HORIZONTAL CNC TURNING CENTRE | CNC | LOKESH | 30 |

| SPECIAL PURPOSE MACHINES | SPM | PART PROCESS LINES | 71 |

| GENERAL PURPOSE MACHINES | GPM | LATHE, VM, HM, RDL | 22 |

| JIG BORING MACHINE | SIP | 1 | |

We are IATAF, BIS and ZED certified

Gray Iron

SG Iron

Our integrated manufacturing and design expertise means we take your project from concept to completion, offering a diverse range of high-value products.

With a diversified business model, we're ready to adapt alongside you, regardless of future technological advancements. Your success is our priority.

Our long-standing customer relationships across industries are a testament to our commitment & reliability. Our commitment to delivering quality products.

C 94, Phase VII, Industrial Area SAS Nagar (Mohali), Chandigarh

Call

+91-172-5008900, 5008901

Email

info@pritikagroup.com

© 2024 Copyright. All Rights Reserved

Designed by AMS Informatics